Mining Rig Build Log - 1

I've decided to join the recent trend of mining cryptocoins with GPUs. First, I got a GPU (an EVGA 1070) to complement my 970 and stuck it in my desktop. This is nowhere near profitable because I'd have to block an I7 machine to mine on 2 cards, and also get annoyed because I can't use it. also, rather than my previous attempt few years back using a couple of cards stuck in a desktop PC and having all family complaining of the noise, I've decided to build a proper rig and have them complain even more! :)

Now, when looking at dedicated rigs, I'd needed something which can support 8 cards (or more?). Unfortunately, the running price for the metal frame is about 250Eur. It looks nice TBH, but I'd rather spend it on a GPU :). Enter DIY.

Hardware

Components:

- 8 L-shaped metal rods 1 meter long, 1.5mm thick, with 1cm each side (4eur/piece)

- 1 square-shaped rod, 1 meter long, 1mm thick, 1.5cm square side (9eur/piece)

- many M3 screws (15mm long are OK) (5eur)

- a Plexiglas sheet (150x100x0.5 cm) (about 15 eur, but I had it lying around). Otherwise, it's probably better to go for an alu piece.

- M2.5 standoffs (2eur)

Total: approx 65 Eur

Tools:

- a drilling machine

- filing tools

- a Dremmel

- sandpaper

- hot glue gun

- ATX motherboard 1:1 printed on an A3 (optional)

The rig frame shape

I've seen some rigs with complex shapes for the GPU section (likely to save on cost), but I chose to build a parallelipipedic (rectangular bar) variant. This also allowed me to use L-shaped profiles for aluminium bars too.

Designing the base frame

The base frame needs to hold the PSU(s) and the motherboard. Eventually, it might need to also hold a PCI-E 3-4 riser.

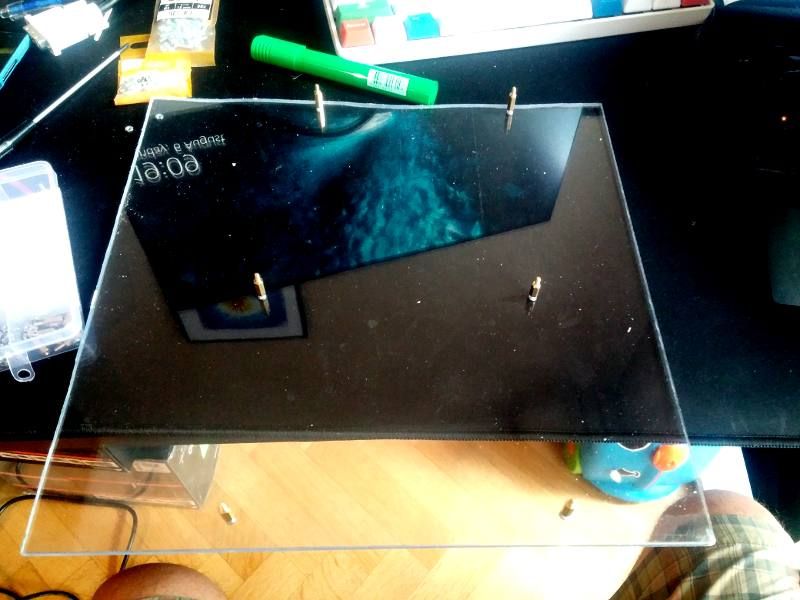

I've seen quite a lot of pics where the mobo was placed flat on the ground/base. Initially, I wanted to create an aluminium flat base for everything, but I had the plexi sheet lying around and I figured I could at least get my motherboard on it. So I:

- cut a piece a bit larger than the motherboard,

- marked the holes for ATX screws using the print (frankly, I used the mobo itself because I could not find the print ATM)

- fixed the standoffs

The finished sheet looks like this:

I've taken this approach to make the rig more transportable. Unfortunately, there are consequences:

- I'd need some sort of railings on the base frame to hold this in place.

- I could not use the same approach for the PSU. I'll have to procure some aluminium sheets.

The frame looks like this (sorry, no interim pic):

You could probably see I used the hot glue to fix the plexiglass sheet and there's also some padding because I've tried initially to put the motherboard directly on the rails. I figured afterwards the motherboard is too flexible for my comfort and I build the plexiglass plate

A note for the future is: Hot glue is not ideal because now I'll have difficulties to remove the rods.

Some comments

- 2m rods are cheaper but more difficult to transport.

- In retrospect, I'd now use square-shaped rods for the frame with plastic joints because it's more elegant than having 20+ screws holding the thing together.